Tools for polymer micro- and nano-replication.

Choosing the right tool.

Replication tools can be divided into two main categories:

Hard-tools and Soft-tools

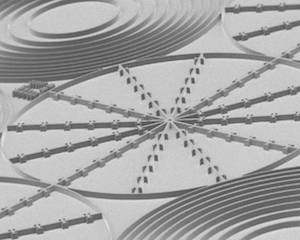

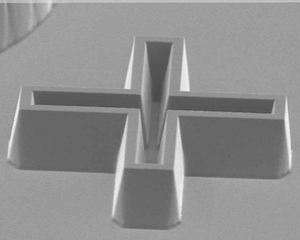

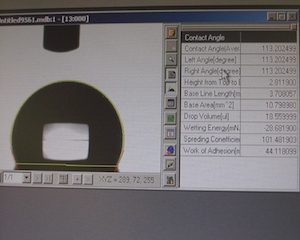

Soft-tools or soft-stamps are basically flexible PDMS-stamps casted from a patterned substrate. The pattern thus is inverted and mirrored with respect to the original. Soft tools are primarily used for hot-embossing small lot sizes; as needed for research purposes.

Application: nano- and microoptics, microfluidics.

PDMS-stamp (silicone) for soft-embossing.

PDMS-stamp (silicone) for soft-embossing.

Hard-tools can be sub-classified into the following 3 categories:

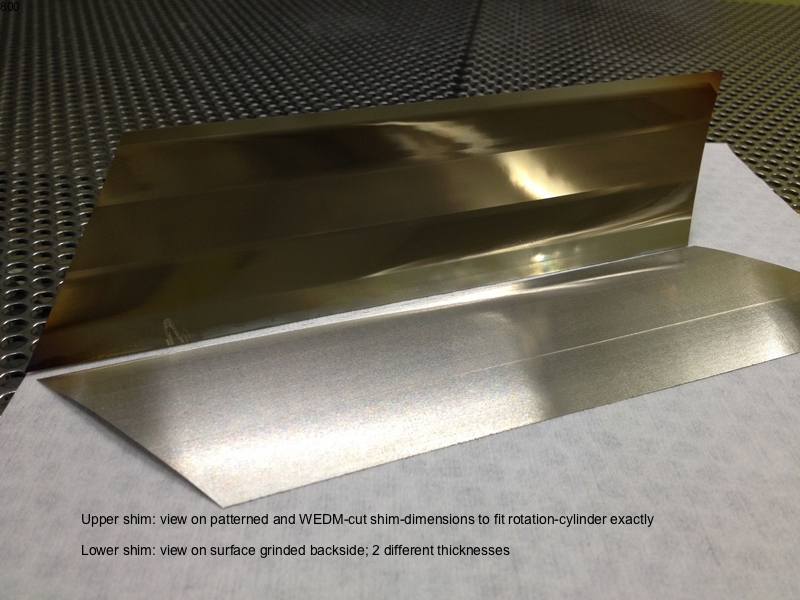

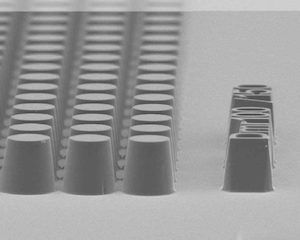

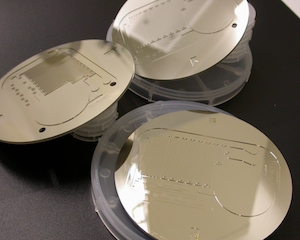

1. Flexible Nickel-shims with a thickness range 0.25 – 0.5mm. They are mainly used on roller-embossing equipment where the thin shim is mounted on a rotating cylinder. Reel-to-reel embossing of nanopattern (holograms or security features) are the main application.

Shim material: EF-Nickel is the only shim material available.

Application: nano- and microoptics, microfluidics.

2 Nickel-shims for roller-embossing

2 Nickel-shims for roller-embossing

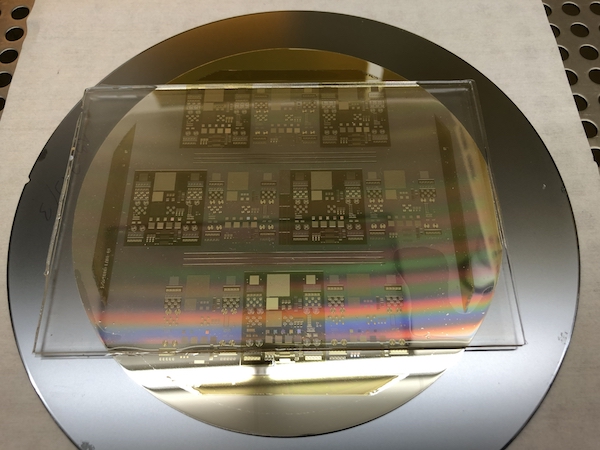

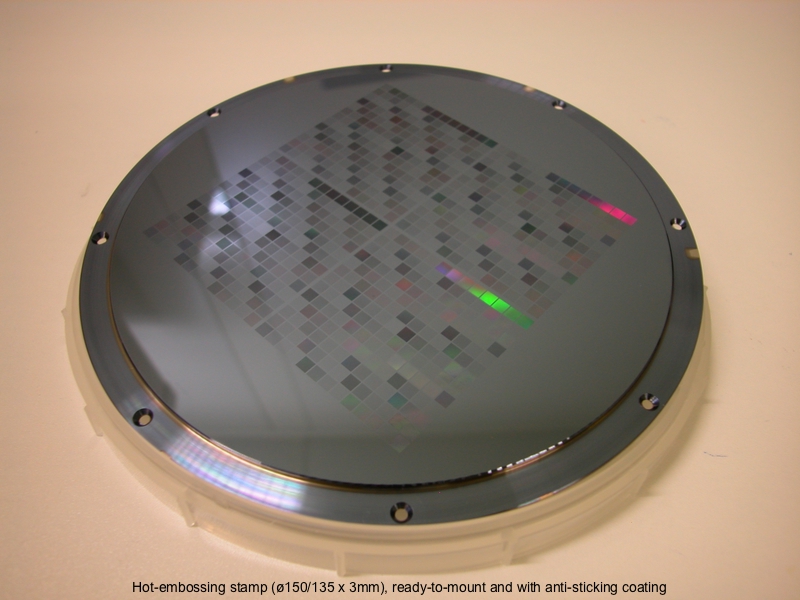

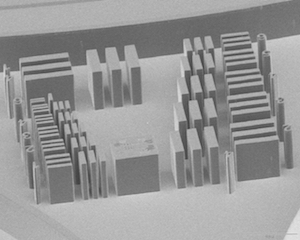

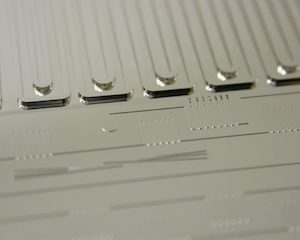

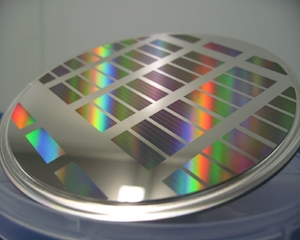

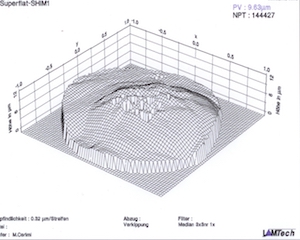

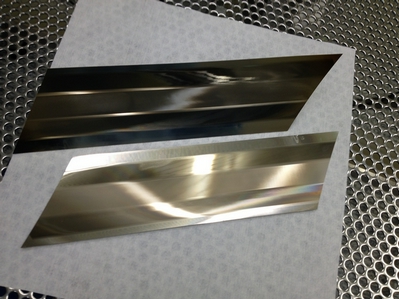

2. Master with a thickness range 0.5 - 3mm are being used on hot-embossing machines. Preferably called “stamp ".

The stamp is being screwed tightly to either heated base plate. An excellent physical contact between hotplate and stamp is vital to ensure proper thermal coupling.

Stamp material: PDMS (silicone) soft stamp, silicon wafer, EF-Nickel or Steel-stamps

Application: nano- and microoptics, microfluidics.

2 Nickel-stamps showing front- and backside. Frontside with antisticking-coating. Backside is polished.

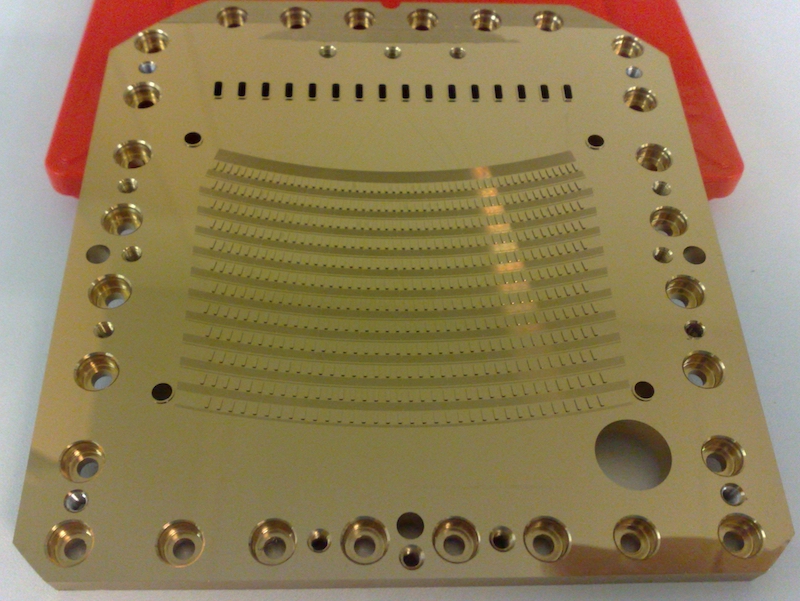

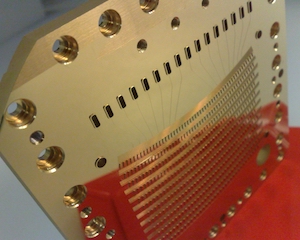

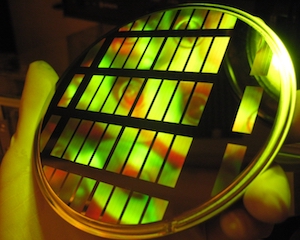

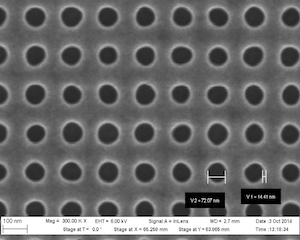

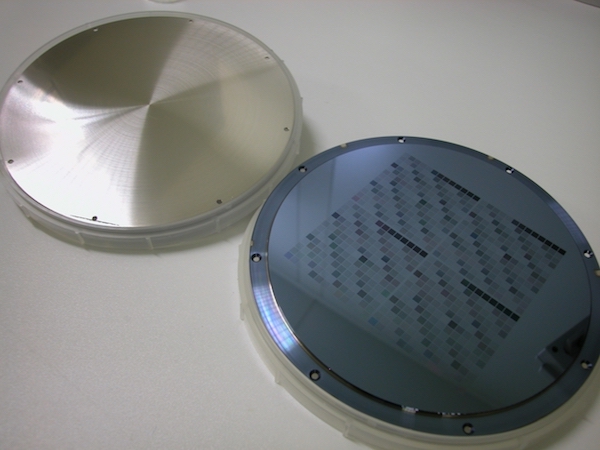

3. Master with a typical thickness range 3 - 8 mm are being used on injection molding machines. Preferably called: “ Inserts ”.

Large area inserts usually have a more massive backplate in order to avoid bending while de-molding. In addition to the higher thickness, inserts are being kept in place with a holding down clamp around its perimeter. Excellent thermal coupling is of great importance to achieve uniform molding behavior.

Insert material: EF-Nickel or milled stainless steel

Application: nano- and microoptics, microfluidics.

Nickel-insert (127 x 127 x 6mm) and TiN wear-resistant coating

Nickel-insert (127 x 127 x 6mm) and TiN wear-resistant coating