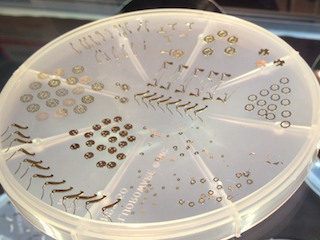

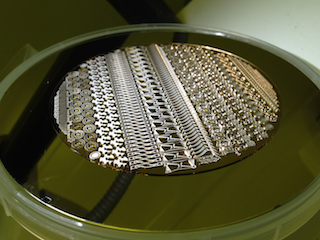

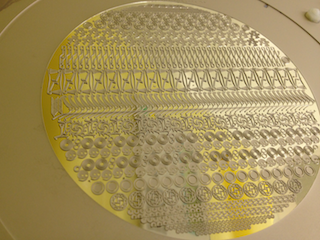

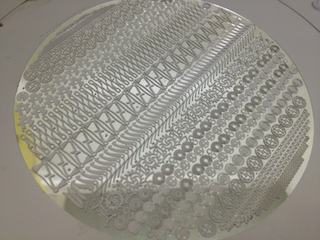

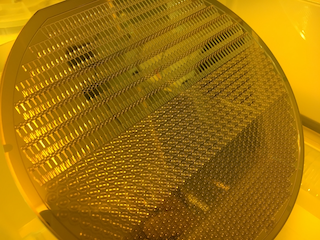

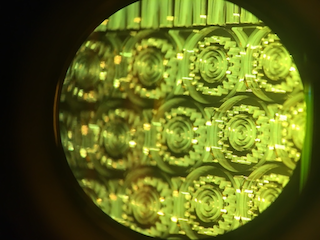

High definition microstructured Watch components.

Characteristics:

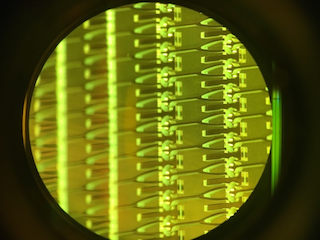

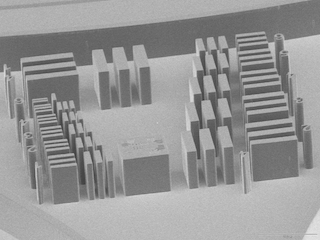

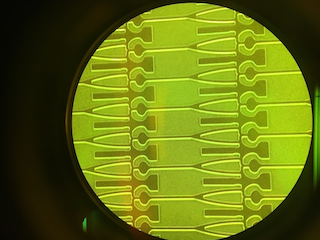

Our high-definition watch components are made using the very versatile UV-LiGA process with photoresist features defining an inverted shape of the final part-geometry. More than any other category, microparts need to have vertical sidewalls in order to function mechanically.

Material: Nickel-Phos12 (580HV), non-magnetic, stainless

Applications: High-definition UV-LiGA watch-components

Specifications:

- Pattern size ≥ 5µm

- Part thickness = 20 - 500µm

- Material: Nickel-Phos12 (580HV), non-magnetic, stainless

- Aspect ratio = 5 - 6 (depends on pattern-design)

- EXCLUSIVE: Adjustable pattern-tapering up to ‹ 15°

- Manufacturing according to adapted LiGA-process

- Multilevel pattern available (e.g. for gearwheel-systems)

- Alignment-precision: level-to-level ≤ 3μm

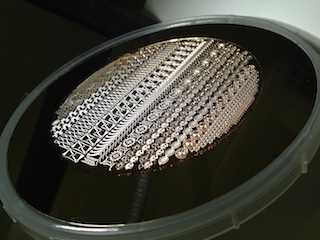

- Maximal patterned area = 200 x 200mm

- Parallelism Frontside-to-backside ≤ 10μm

- Available PVD-coatings (e.g. noble metals, wear-resistant coat.)

- Compatible photoresist for UV-lithography:

AZ positive resists, Microchem SU-8

Click here to open printer-ready version

1. Convert customer data into Maskdesign

2. Fabrication of maskset

3. Lithography on substrates =» resist-mold

4. Prepare the resist-master for Ni-electroforming

5. Lapping excessive Nickel to final thickness and surface finishing (polishing)

6. Removal of resist

7. Optional coating with noble metal or wear-resistant coating