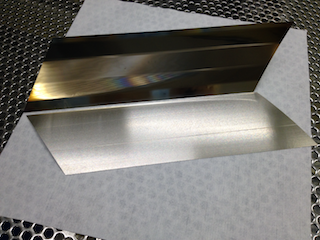

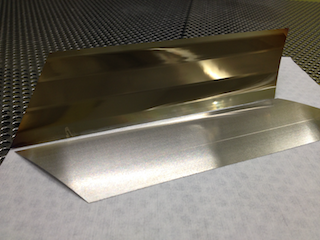

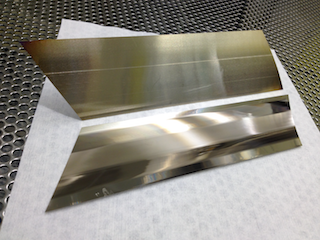

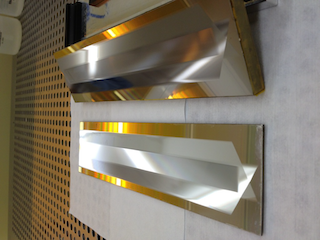

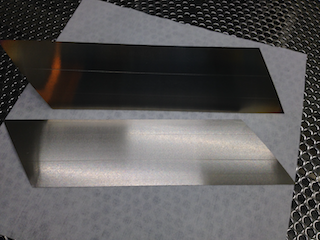

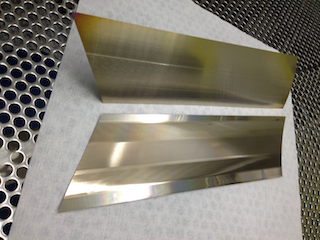

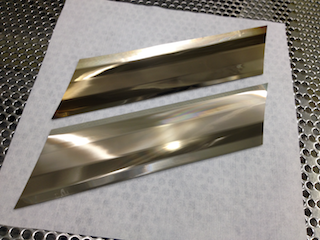

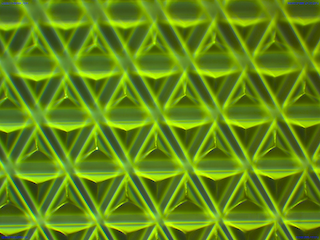

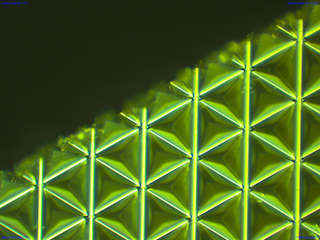

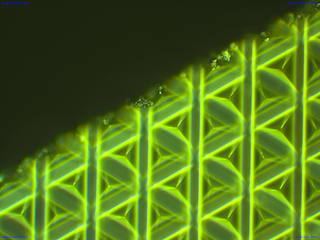

Roller-embossing shims

Characteristics:

Flexible Nickel-shims with a thickness range 0.25 – 0.5mm. They are mainly used on roller-embossing equipment where the highly flexible Ni-shim is mounted on a rotating cylinder. Reel-to-reel embossing of nanopattern (holograms, anti-counterfeiting, micro-optics or security features) are the main applications.

Material: EF-Nickel

Applications: Nano- and microoptics, microfluidics.

1. Manufacturing a brass/NiP =» master

2. Prepare the master for Ni-electroforming =» sub-master (pattern inverted / mirrored)

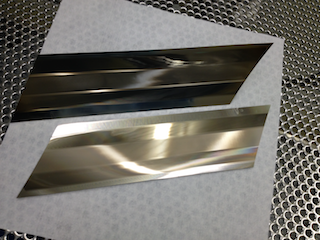

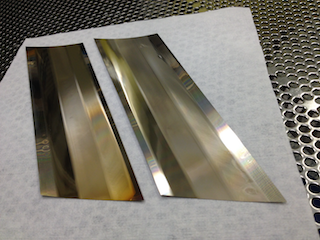

3. Prepare sub-master for Ni- electroforming a thin shim =» working copy (pattern same as master)

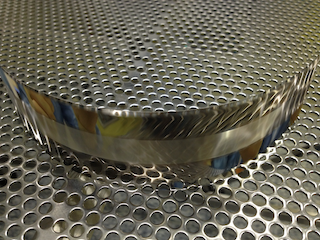

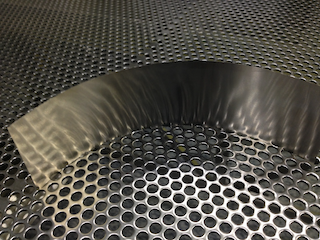

4. Post-processing shape of the shim for mounting on the rotating cylinder

1. UV-lithography a resist coated substrate =» master

2. Prepare the master for Ni-electroforming =» sub-master (pattern inverted / mirrored)

3. Prepare sub-master for Ni- electroforming a thin shim =» working copy (pattern same as master)

4. Post-processing shape of the shim for mounting on the rotating cylinder.

Specifications:

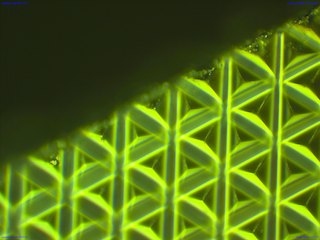

- Pattern size range ≥ 70nm

- Pattern height/uniformity = 50nm – 50µm / 5%

- EXCLUSIVE: Adjustable drafted sidewalls up to 15° (easy demolding)

- Manufacturing according to adapted LiGA-process

- Multilevel pattern available (micro+nano)

- Alignment-precision: level-to-level ≤ 3μm

- Alignment-precision: micropattern to machined features ≤ 20μm

- Shim thickness: 0.25 – 0.5mm

- Maximal shim dimensions= 300 x 300mm

- Maximal patterned area= 200 x 200mm

- Parallelism Frontside-to-backside ≤ 10μm (Backside: surface grinded)

- Robust handling

- Ready-to-use shims according to customer drawing

- Contour wire-electrodischarge machined (tolerance: ±10µm)

- Available antisticking-coating (fluoro-based)

- Available wear-protection coating (TiN)

- Compatibility to diamond milling

- Compatibility to most patterning methods: - e-beam resists (PMMA, HSQ)

- XIL-resists

- AZ positive resists, Microchem SU-8

- Hot-embossed polymers, Thermal imprinting,...