Services and Engineering: IV

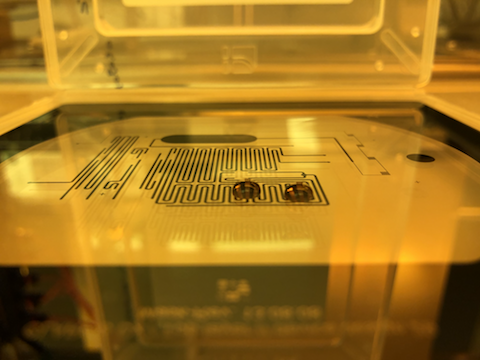

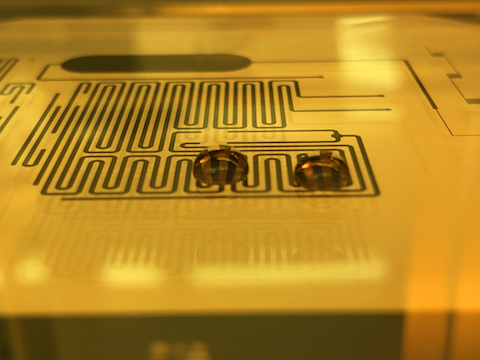

Antisticking-coating service:

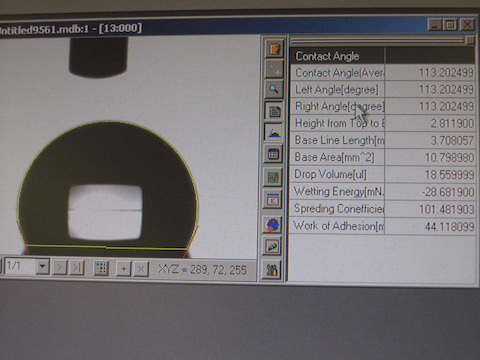

Antisticking layers (ASL) are available for replication tools as well as for lithography-masks.

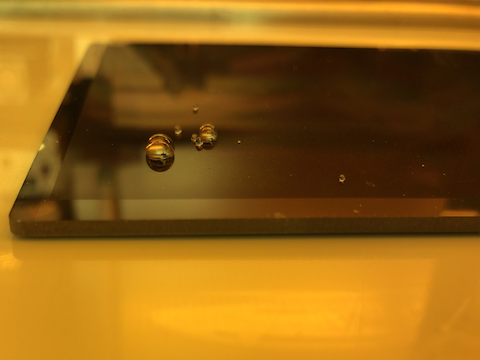

ASL are a very useful added functionality to our products when easy mold-separation is essential for your replication process.

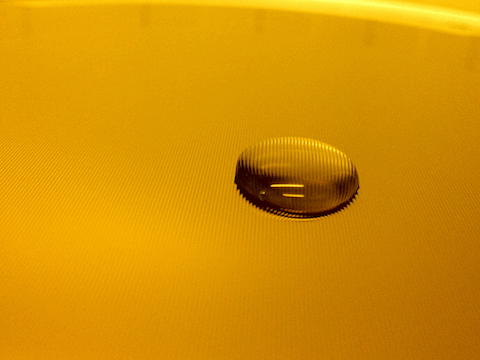

We do also offer anti-sticking coatings for lithography-masks. An additional ASL can become the best measure to reduced sticking forces between mask and resist-coating. This is very helpful way to avoid mask-contamination due to resist-voids, thus increasing "operating-hours-between-cleaning". This is particularly crucial with thick resists (e.g SU-8) and -inherently- long exposure durations.

Our ASL coatings still allow the use of organic solvents (Aceton, IPA, etc.) for intermediate mask-cleaning.

Antisticking-coatings are Si-F based and can be refreshed and thereby substantially extending mask-life.

Specifications:

Type of the ASL-coating:

Fluoro-Silane.

Additional SiO2 base coating may be required (Thickness = 20 - 50nm)

Coating available for these substrate materials:

Glass (e.g.Sodalime or Quarz for lithography-masks)

Silicon, Nickel, Steel

Substrate formats:

Round substrates: ø100 - ø300mm

Square substrates: 4", 5", 6", 7", 9"

Replication tools: any shape of shims, stamps or inserts

Process flexibility:

Other substrate-formats or substrate-material on request.

1. Customer sends pattern-design (CAD-file, sketch,...)

2. applied microSWISS takes care of maskset-manufacturing

3. SiO2 coating (thickness = 50nm) onto mask

4. CVD processing to apply Antisticking coating

5. Packaging processed mask in original container

6. Shipping with appropriate remarks for handling, cleaning and storage

1. Customer sends pattern-design (CAD-file, sketch,...) for stamp

2. applied microSWISS to manufactures the hot-embossing stamp

3. SiO2 coating (thickness = 50nm) onto mask

4. CVD processing to apply Antisticking coating

5. Packaging processed stamp in appropriate container

6. Shipping with appropriate remarks for handling, cleaning and storage