Manufacturing Basics.

History.

The LiGA-process has initially been developed at the Forschungszentrum Karlsruhe, Germany. It is using collimated hard X-ray (synchrotron storage ring) radiation to expose high-aspect ratio PMMA-microstructures with feature heights up to 1000µm. This radiation is only available from extremely expensive large research facilities. The need for this kind of radiation is the main drawback and therefore is not commercially competitive for industrial use.

The applied microSWISS-Highlights.

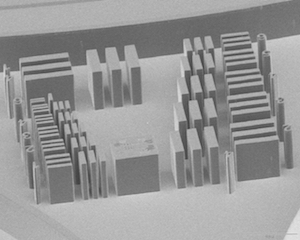

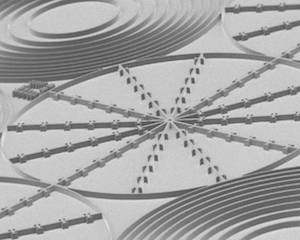

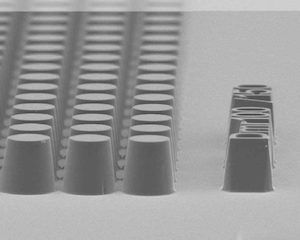

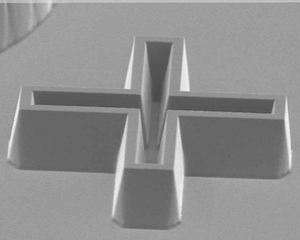

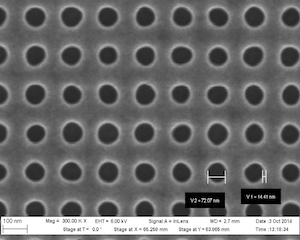

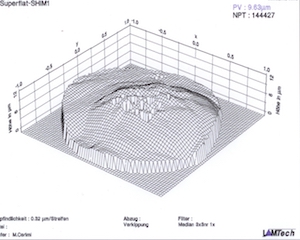

Micropatterned structures with the following characteristics can be built using UV-Lithography:

• Pattern heights from 50nm up to 500µm

• Aspect ratio(AR) = 5:1 (Pattern-height / feature width)

• Excellent sidewall steepness

• Surface roughness (Ra) ‹ 6nm

• Very tight tolerances achievable

• microSWISS-exclusivity: Sidewalls with adjustable draft angle for replication tools.

applied microSWISS: Your one-stop-shop.

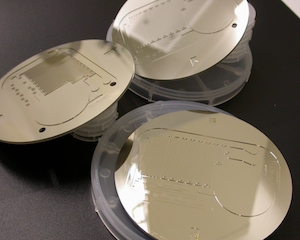

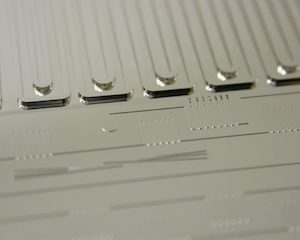

Over the past 20+ years, microSWISS has developed and established a very comprehensive process portfolio for various pattern heights and multi-level architectures. This allows us to address increasingly demanding micropattern specifications from the polymer replication community.

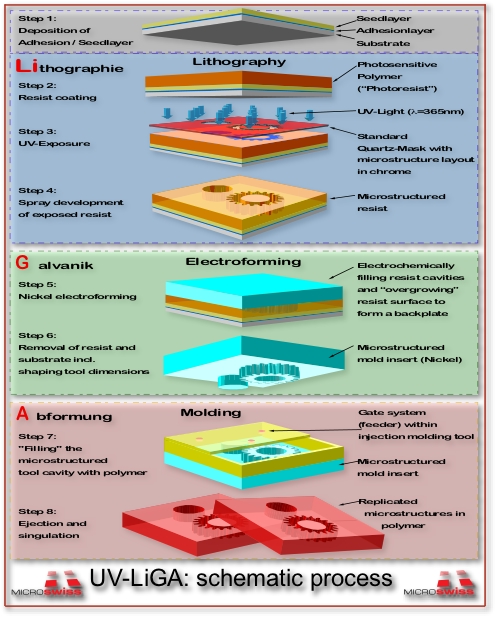

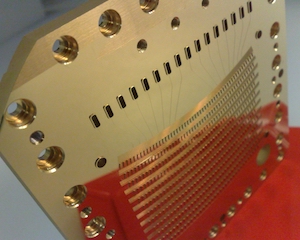

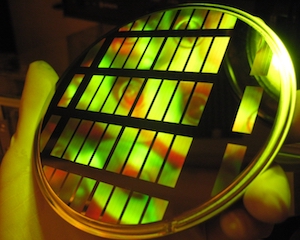

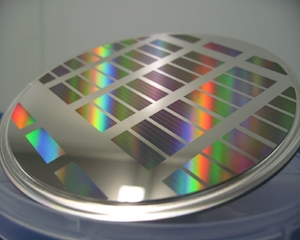

The LiGA process is used to manufacture micro- and nanostructures in metal as well as replication tools.

The schematic process flow shows the essential process steps.

The applied microSWISS-Solution.

The founder and CEO of microSWISS is one of the pioneers of the UV-LiGA technique and has published this affordable alternative in scientific papers as early as 1997.

This cost-effective and easier available alternative is using collimated UV-light with a wavelength of 365nm. These narrow bandwidth light sources are built in MEMS mask-aligners and can be found in well-equipped micro-structuring labs.

Alternative names are low-cost LiGA or HARMS-process.