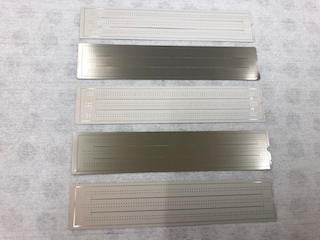

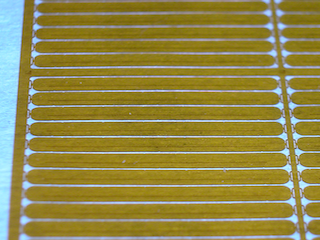

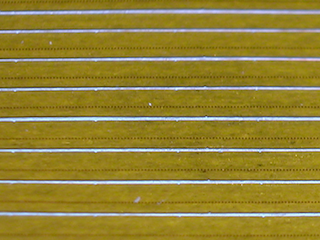

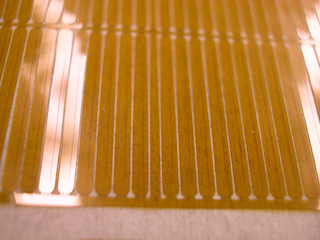

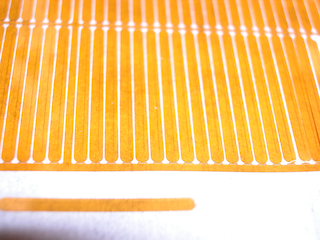

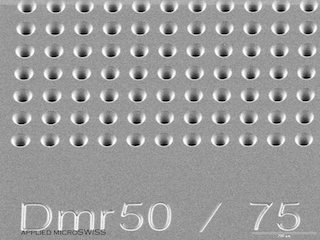

High definition microstructured Nozzle plates.

Characteristics:

microSWISS is taking manufacturing Nozzle plates to a new level of innovation.

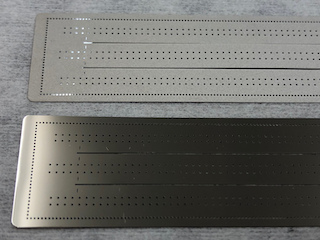

Conventional patterning methods use overgrowing a resist pattern during electroforming or laser-drilling to achieve the orifices in the nozzle plate. The disadvantages are limitations in orifice-geometry, surface roughness (laser-induced build-up of corner burr) and orifice proximity.

Our nozzle plates are made using the very versatile UV-LiGA process which delivers extremely smooth surfaces and circularity ("roundness")on the orifices. The result is very uniform micro-droplet formation across the nozzle plate. This is a new manufacturing approach to take full use of the advantages of microtechnology.

These high-pattern definition plates are being used for a variety of droplet-generating systems such as inkjet-printing and injector-systems.

Material: EF-Nickel, fully-crosslinked Photo-Epoxy (SU-8)

Applications: Various spray- or droplet-generating systems

Specifications:

- Pattern size ≥ 5µm

- Nozzle thickness = 20 - 500µm

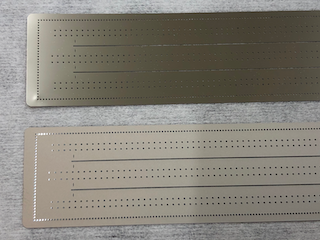

- Material: Nickel, Nickel-Phos12 (580HV), fully crosslinked Photoexpoxy (SU-8)

- Aspect ratio = 5 - 6 (depends on pattern-design)

- EXCLUSIVE: Adjustable conical orifices ‹ 15°

- Manufacturing according to adapted LiGA-process

- Multilevel pattern available (e.g. for integrated microfluidics)

- Alignment-precision: level-to-level ≤ 3μm

- Maximal patterned area = 200 x 200mm

- Parallelism Frontside-to-backside ≤ 10μm

- Available PVD-coatings

- Compatible photoresist for UV-lithography:

AZ positive resists, Microchem SU-8

Click here to open printer-ready version

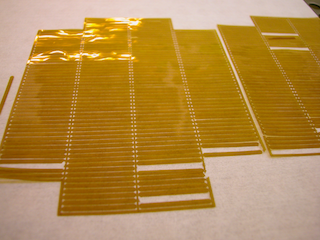

1. Convert customer data into Maskdesign

2. Fabrication of maskset

3. Lithography on substrates =» resist-mold

4. Prepare the resist-master for Ni-electroforming

5. Removal of resist and release from wafer