Services and Engineering: I

Resist coating service:

applied microSWISS is offering a resist coating service to its customer.

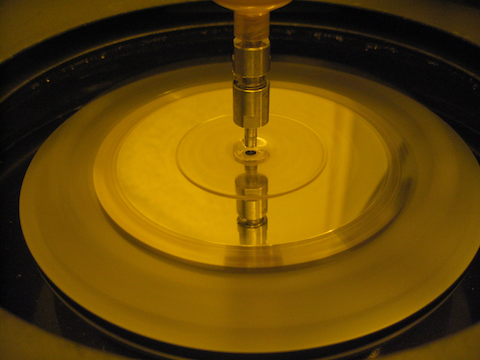

Lithographic processes begin with a perfectly coated photoresist. Coating uniformity and proper softbake are essential.

We have extensive knowledge in photoresist-processing and it starts with substrate preparation (e.g. cleaning, dehydration and adhesion promotor).

We have identified our photoresist-processes as a very precious asset and constantly keep improving it.

We also take great precaution on particle contamination and are well equipped and trained to deliver high-quality coated wafers, glass-plates and other customer substrates.

Specifications:

List standard available photoresists:

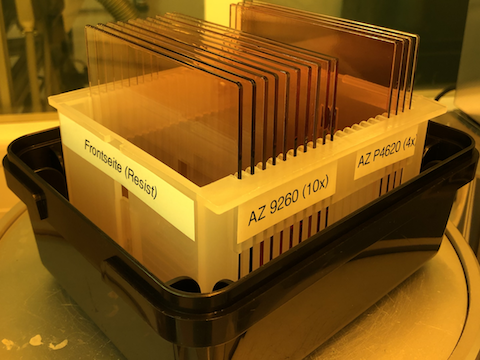

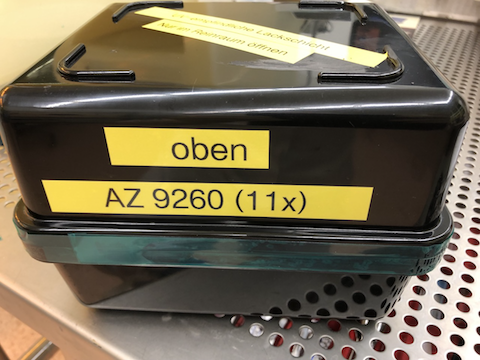

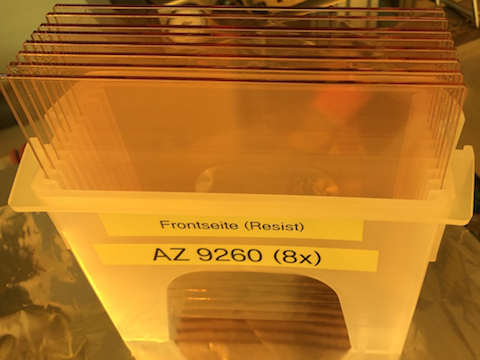

Various positive-tone Merck AZ resists for the full range of thicknesses.

Megaposit SPR 220 series

Kayaku (former: MicroChem) Photoexpoxy SU-8, KMPR

Image reversal Lift-off (AZ nLOF 20xx, TI35 ES, TI35 ESX)

Substrate formats:

Round substrates: ø100, ø150, ø200, ø300mm

Square substrates: 4", 5", 6", 7", 9"

Available Resist thickness:

Positive-tone resists: 100nm - 80µm (e.g. AZ resists)

Negative-tone resists: 3µm - 550µm (e.g. SU-8)

Process flexibility:

Other resists, substrate formats or resist thicknesses on request.

1. Customer sends substrates in cleanroom-compatible container

2. Substrate inspection and preparation (cleaning + adhesion promotor)

3. Resist coating and softbake with superior uniformity

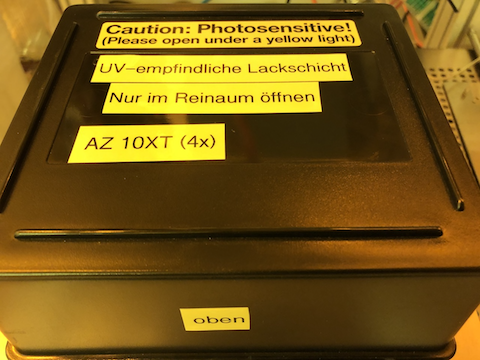

4. Packaging coated wafers in opaque container

5. Shipping with appropriate remarks for handling, care and storage

1. applied microSWISS to prepare substrates

2. Substrate inspection and preparation (cleaning + adhesion promotor)

3. Resist coating and softbake with superior uniformity

4. Packaging coated wafers in opaque wafer-box

5. Shipping with appropriate remarks for handling, care and storage

1. Customer sends substrates in cleanroom-compatible container

2. Substrate inspection and preparation (cleaning + adhesion promotor)

3. Resist coating and softbake with superior uniformity

4. Packaging coated wafers in opaque container

5. Shipping with appropriate remarks for handling, care and storage