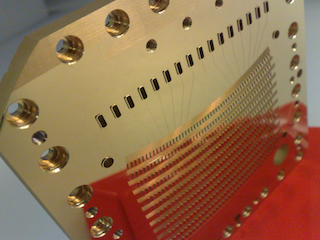

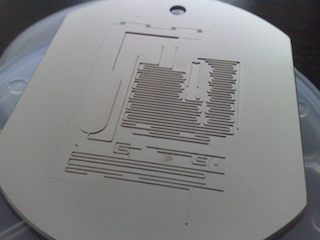

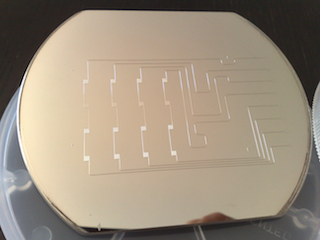

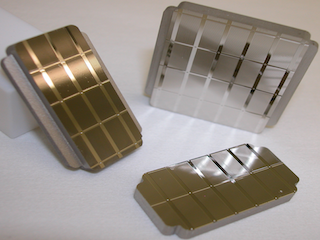

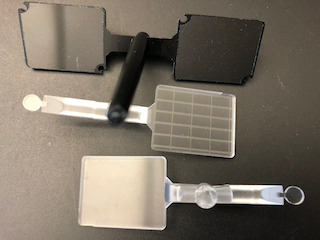

Injection molding inserts

Characteristics:

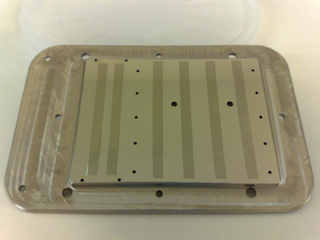

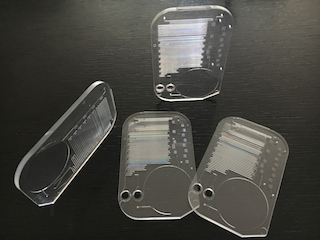

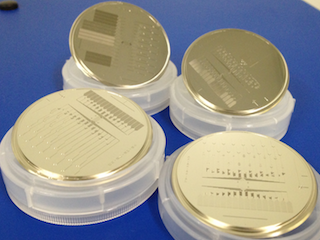

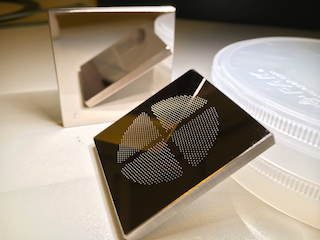

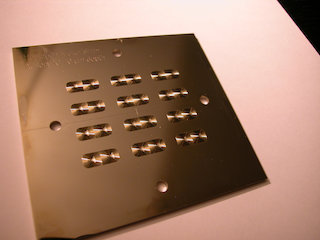

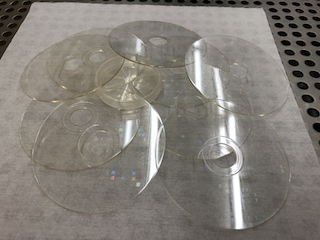

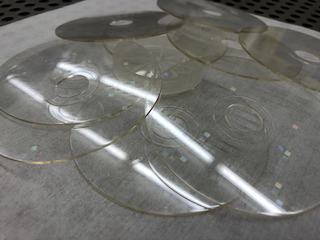

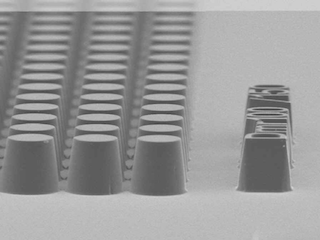

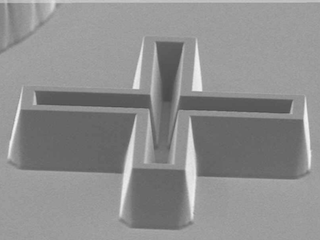

Master with a thickness range 3 - 8 mm are being used on injection molding machines. Preferably called: “ Inserts ”. Large area inserts usually have a more massive backplate in order to avoid bending while de-molding. In addition to the higher thickness, inserts are being kept in place with a holding down clamp around its perimeter. Excellent thermal coupling is of great importance to achieve uniform molding behavior.

Material: EF-Nickel or Steel

Applications: Nano- and microoptics, microfluidics.

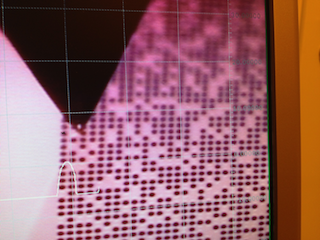

1. Convert customer data into Maskdesign

2. Fabrication of maskset

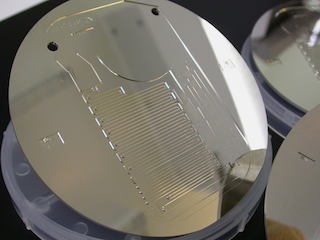

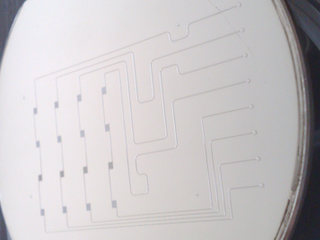

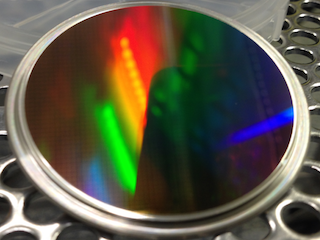

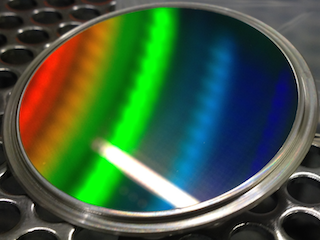

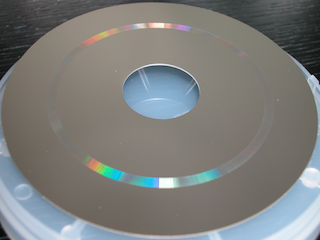

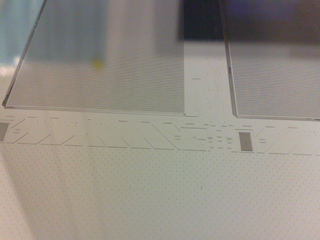

3. Lithography on substrates =» resist-master

4. Prepare the master for Ni-electroforming =» Nickel-master (pattern inverted / mirrored)

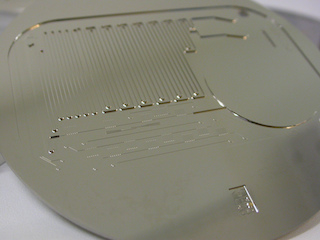

5. Removal of wafer and resist

6. Mechanical post-processing the geometry of the insert for mounting in the injection molding machine.

1. Prepare the customer-substrate for Ni-electroforming =» Nickel-master

2. Removal of wafer and resist

3. Mechanical post-processing the geometry of the insert for mounting in the injection molding machine.

1. Prepare the customer-substrate for Ni-electroforming =» Nickel-master

2. Removal of wafer and resist

3. Prepare Nickel-master for Ni-electroforming =» Nickel-copy

4. Mechanical post-processing the geometry of the insert for mounting in the injection molding machine.

Specifications:

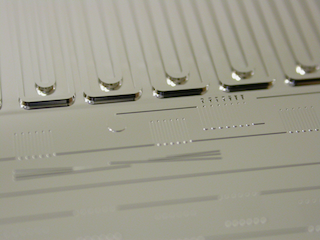

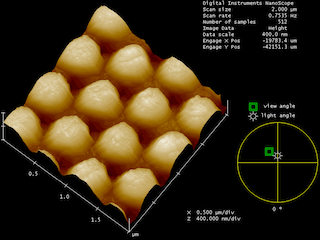

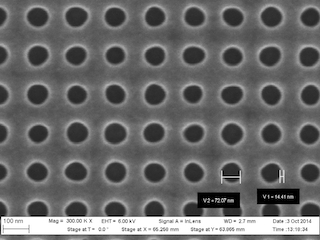

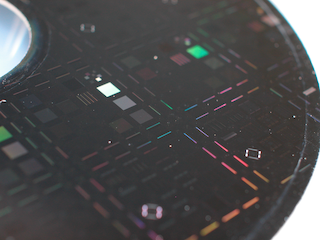

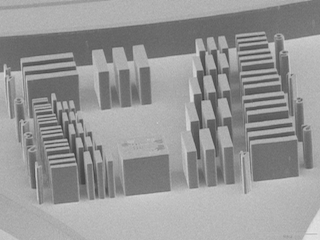

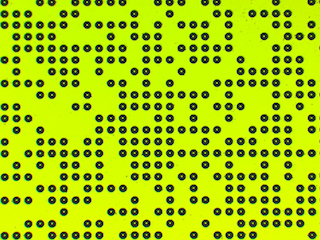

- Pattern size range ≥ 70nm

- Pattern height/uniformity = 50nm - 500µm / 3 – 5%

- EXCLUSIVE: Adjustable drafted sidewalls up to 15° (easy demolding)

- Manufacturing according to adapted LiGA-process

- Multilevel pattern available (micro+nano)

- Alignment-precision: level-to-level ≤ 3μm

- Alignment-precision: micropattern to machined features ≤ 10μm

- Mold thickness = 3 - 8mm

- Maximal mold dimensions = 300 x 300mm

- Maximal patterned area = 200 x 200mm

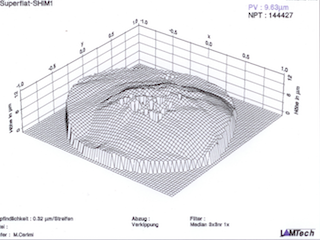

- Parallelism Frontside-to-backside ≤ 20μm (Backside: surface grinded)

- Robust handling

- Integration of mechanical mounting features

- Ready-to-use mold-inserts according to customer drawing

- Contour wire-electrodischarge machined (tolerance = ± 10µm)

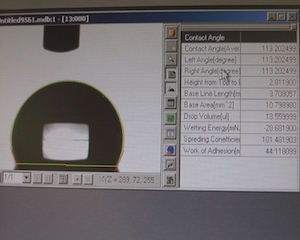

- Available antisticking-coating (fluoro-based)

- Available wear-protection coating (TiN)

- Compatibility to most patterning methods: - e-beam resists (PMMA, HSQ)

- XIL-resists

- UV-lithography: AZ positive resists, Microchem SU-8

- Hot-embossed polymers, Thermal imprinting,...